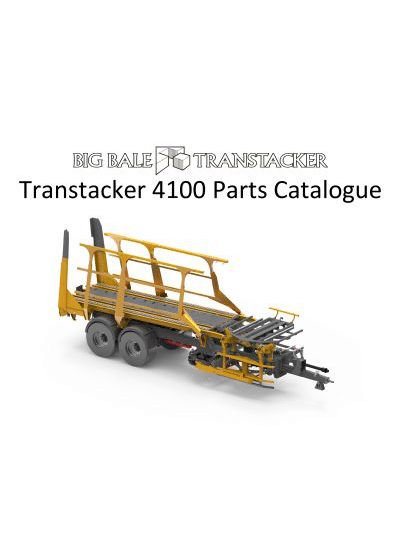

Big Bale South is the exclusive worldwide supplier of the Big Bale Transtacker, the industry-leading bale collector designed for fast and efficient bale collection, stacking, and transport.

Engineered to streamline your bale handling operations, the Transtacker eliminates the need for additional equipment like telehandlers, making it an all-in-one solution for moving large square bales with ease. Built to ISO 9000 standards, each machine is factory-produced for reliability and quality, with customizable options to fit your specific needs.

The fully automated system increases efficiency by picking up and tying bales in a stable stack, allowing for faster field clearance—crucial during harvest in unpredictable weather.

The Transtacker 4100 can handle five different bale sizes, re-pick existing stacks, and perform part loads, giving operators complete flexibility.

With standard features like air brakes, low ground pressure tyres, reversing camera, led lighting package and a hydraulically adjustable drawbar, the Transtacker is designed for maximum performance and operator convenience.

Backed by a full manufacturer’s warranty, this bale collector is ready to transform the way you handle bales—faster, safer, and more efficiently than ever before.

New & used machines available & ready to work

With the push of a button, the Transtacker seamlessly transitions into Auto Mode, enabling fully automated bale collection and transport without requiring manual joystick operation or operator input.

Before activating Auto Mode, the operator can configure key settings, including bale size, stacking pattern, and the number of layers required before the machine transitions into Road Mode. This ensures precise, stable stacking while minimising operator error and simplifying the process.

Once Auto Mode is engaged, the Transtacker opens for bale collection, as seen on the video above. As bales are added, the in-cab display provides a real-time view of the stacking progress, allowing the operator to monitor layers and optimise efficiency.

When the machine reaches full capacity, it automatically alerts the operator and transitions into Road Mode, securing the load for safe and efficient transport.

The CTF Grab Arm enables the Transtacker to pick up bales from various angles, reducing the need for precise alignment. In Auto Mode, simply push a bale into the hydraulically dampened Bump Paddle, which automatically initiates the Pick-Up Sequence. The Grab Arm secures and aligns the bale against the Pick-Up Frame, lifting it clear of the ground without slowing forward speed.

The bale is then placed onto the Turntable, pushing any previously collected bales to the far side. The tines retract, and the Pick-Up returns to its home position, ready for the next bale in one seamless, automatic motion.

The Pick-Up height is adjustable to accommodate different bale sizes, ensuring smooth placement on the Turntable. When switching to Road Mode, the Pick-Up automatically raises for increased ground clearance while traveling.

For safety, the Guide Bar and Grab Arm retract when Road Mode is engaged or when the Transtacker reaches full capacity. Two spare tines are also mounted on the chassis as standard.

The high-capacity turntable is built to handle all compatible bale sizes without the need for modifications or adjustments.

As bales are transferred from the Pick-Up, the Turntable can either raise them in the forward position or rotate 90 degrees. This allows the stack to be tied together for added stability, while a double row of strengthened tines secures the bales in place. The tie-in function is fully automated, based on the operator’s pre-set bale configuration.

Once positioned vertically, the turntable pushes the bales rearward, either forming the base of a new stack or aligning them with previously placed bales.

When the Full Load function is engaged, the turntable remains in place, acting as a clamp to stabilise the stack during unloading at the stack site.

The Side Gates are engineered for maximum strength to maintain a narrow profile & keep machine width and weight optimised.

In Auto Mode, the Side Gates open and close automatically as the Turntable loads bales onto the bed. This ensures that bales remain securely held, even on steep terrain, reducing the risk of tipping or sliding.

When Road Mode is activated, the Side Gates automatically grip the bales, allowing for safe and stable transport to the stack site—without any need for operator adjustments. The Side Gates have the ability to open 90 degrees allowing stacks to be tipped up tightly to a neighbouring stack, maximising storage efficiency.

The Rear Clamps provide exceptional holding force, engaging automatically when a full load is detected. Powered by a powerful hydraulic system, they ensure the bales remain tightly secured during transport and unloading.

The redesigned Top Rear Clamp Paddles make re-picking stacks easier than ever. Even when stacks are placed side by side, the smooth edges prevent damage to bale strings while sliding the clamps in or out.

The Big Bale Transtacker streamlines every stage of bale handling, from part loads to full-stack tipping and collection.

With the Auto Part Load System, the Transtacker automatically detects when a part load is present. A single joystick movement shifts the bales to the back of the trailer, ready for unloading. The system’s Pulley Beam and three-stage cylinder ensure smooth operation, while the adjustable fork cables provide precise calibration for optimal performance.

When tipping a full load, the Turntable, Side Gates, and Rear Clamps hold the bales securely as the machine reverses into position. The stack can be tipped while moving, and with one joystick activation, all clamps release for a quick, efficient drop-off.

The Transtacker also allows for easy re-picking of stacks, making it possible to relocate bales as needed. Simply reverse the tipping process to load stacks back onto the trailer—effortless, precise, and efficient.

New & used machines available & ready to work

New & used machines available & ready to work

Big Bale South offers a comprehensive hire service for both new and secondhand bale chasers, ensuring you have the right equipment to handle your harvest efficiently.

With a large fleet of Transtackers available, we provide flexible, season-long hire agreements with no restrictions on bale movement, allowing you to plan your costs with confidence.

All hired machines come with a manufacturer’s warranty for peace of mind, and operator training courses are available to ensure optimal performance.

The hire agreement covers the entire harvest, with the hirer responsible only for consumable parts, tyre damage, and operator-related issues.

| Model | Duration | Deposit | 25th June | 25th July | 25th August | Total |

|---|---|---|---|---|---|---|

| Transtacker 4100 with PTO driven Hydraulics (Used) | June - September | £4,500 | £5,500 | £5,500 | £5,500 | £21,000 |

| Transtacker 4200 with PTO driven Hydraulics (New) | June - September | £4,500 | £6,500 | £6,500 | £6,500 | £24,000 |

A deposit is required on signing for all machines, with the balance then paid with 3 payments on 25th June, 25th July & 25th August.

Machines that are on our hire fleet will be organised through a finance company.

If you decided to buy the trailer you have hired,on a “sold as seen” basis, by 25th September, we would offer 60% rebate of your hire fee against the purchase price of the machine as stated at the beginning of the hire period.

Operator courses available.

All trailers have a manufacturer’s warranty supplied by Big Bale Co (south) Ltd. (Warranty terms & conditions provided prior to ordering).

3 year hires are available. A three year hire will fix the hire fee for the entire period, it will save on haulage as the trailer will stay at your premises.

We will travel to you to service the machine, you get to keep the same machine for the duration.

The three year hire is organised through a finance company, where you can arrange your annual payment terms to suit your business, last payment needs to be by 25th August in the 3rd year of hire.

Delivery & collection are charged extra.

Financial penalties will apply if any hire agreement is terminated before conclusion by the hirer.

Find out more about the Big Bale Transtacker. Talk to our sales team today to request a demo, brochure or discuss options.

Available now from our UK stock

To allow the Transtacker to operate within the Controlled Traffic Farming criteria, we are offering the New CTF Nudge bar allowing you to collect bales without deviating from the wheelings.

A standard inbuilt hydraulic accumulator dampens the impact loads, reducing stresses on your tractor and increases operator comfort. One double acting front mounted spool valve is required to operate the CTF Nudge Bar.

£6,500 + VAT and delivery. A hire option is available, please get in contact for further information.

If required, bales can be turned onto their sides for collection on the trailer, whether this is for personal preference or you require the strings on the side of the bale.

The front hitch mounted wheeled bale turner can handle any job and comes with hydraulic folding as standard for road transport. One double acting front mounted spool valve is required to operate the wheeled bale turner.

£3,700+VAT & delivery. A hire option is available, please get in contact for further information.

If you have the need to turn the bales through a quarter turn as they leave the baler we can also supply a chute for the rear of the baler.

Our design not only incorporates a full width start to the chute to prevent the bale twisting on exit, it also has a bale drop alarm fitted as standard for easy connection to a Massey Ferguson Baler.

£750.00 + VAT and Delivery

See the Big Bale Co. South Transtacker in action!

Your resource for Transtacker related documents

Find out more about the Big Bale Transtacker. Talk to our sales team today to request a demo, brochure or discuss options.